Revolutionize Grinder Performance with

the Rome BORR System

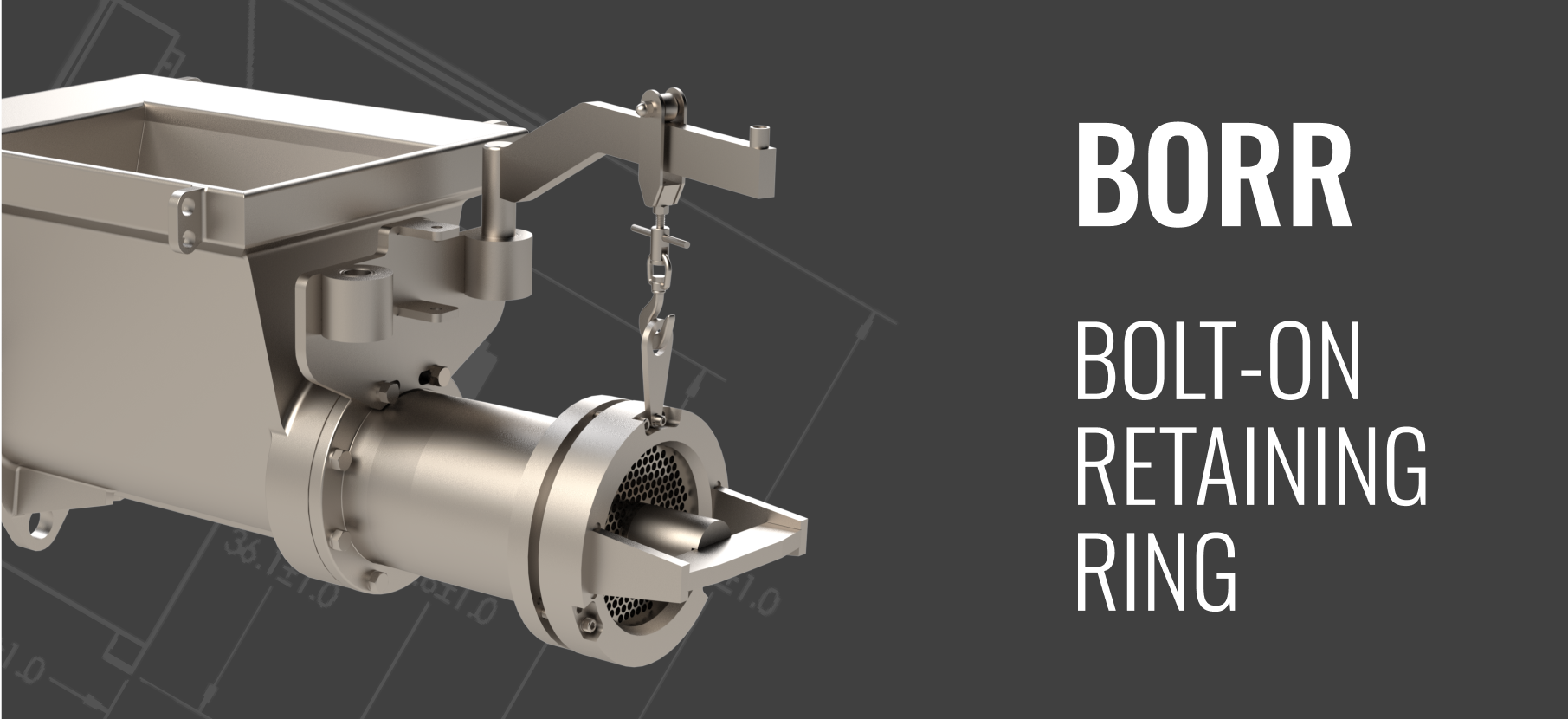

Every minute of downtime during a grinder changeover or maintenance window can lead to lost revenue, product inconsistency, or unnecessary strain on your team. That’s why Rome Grinding Solutions engineered the 14” Bolt-On Retaining Ring (BORR) System—a breakthrough innovation that simplifies operations, enhances safety, and improves long-term equipment performance.

What Is the BORR System?

The BORR is a bolt-on, threadless retaining ring system designed to replace traditional threaded components in 14” industrial grinders. Traditional rings often seize, require excessive torque, and slow down plate or knife replacements. The BORR eliminates these inefficiencies with a smart, captured-bolt design that’s faster, safer, and easier to maintain.

Rome’s BORR system is compatible with new grinders and can be retrofitted to existing units—offering flexibility for food production facilities looking to upgrade without overhauling.

Key Benefits of the Rome BORR System

Enhanced Safety & Simplicity

- No More Threads: The BORR eliminates threaded connections, reducing the risk of injuries from seized or overtightened rings.

- Reduced Physical Strain: Operators can complete changeovers without excessive force or specialized tools.

- Contamination Prevention: Captured bolts prevent loose parts from falling into product zones during changeovers.

Increased Productivity & Uptime

- Fast Changeovers: Maintenance teams can perform plate and knife swaps in minutes—not hours.

- Consistent Grind Output: The BORR applies even pressure across grind plates, improving product texture, definition, and yield.

- Ideal for High-Speed Operations: Minimizes downtime and keeps production moving efficiently.

Cost-Efficiency & Extended Equipment Life

- Longer Part Lifespan: Even torque distribution reduces wear on high-cost cutting parts like knives, plates, and rings.

- Lower Maintenance Costs: Fewer breakdowns, less emergency service, and minimal unplanned interruptions.

- Optimized Labor Utilization: Simpler operation means teams spend less time on maintenance and more time on production.

Built for Food Production in the Real World

We understand the daily realities of industrial food manufacturing—because we design and build the grinders that power their lines. The BORR system was developed by engineers who know how small changes in grinder performance can lead to major gains in efficiency, safety, and consistency across beef, pork, poultry, dairy, seafood, and pet food production.

Looking for real-world proof? Read how one food production company improved efficiency and changeover safety in this BORR system case study.

Ready to Upgrade?

Whether you’re designing your next production line or upgrading existing equipment, the Rome BORR System helps you maximize uptime, ensure operator safety, and reduce wear on critical components.

Call the Rome Sales Team at (800) 443-0557

Email Sales@RomeGrindingSolutions.com

1427 Western Avenue

Sheldon, IA 51201

PO Box 186

800-443-0557