Meet the Colossus: The Future of

Frozen Block Grinding Is Here

Debuting at IPPE 2026 in Atlanta | Booth #C20139

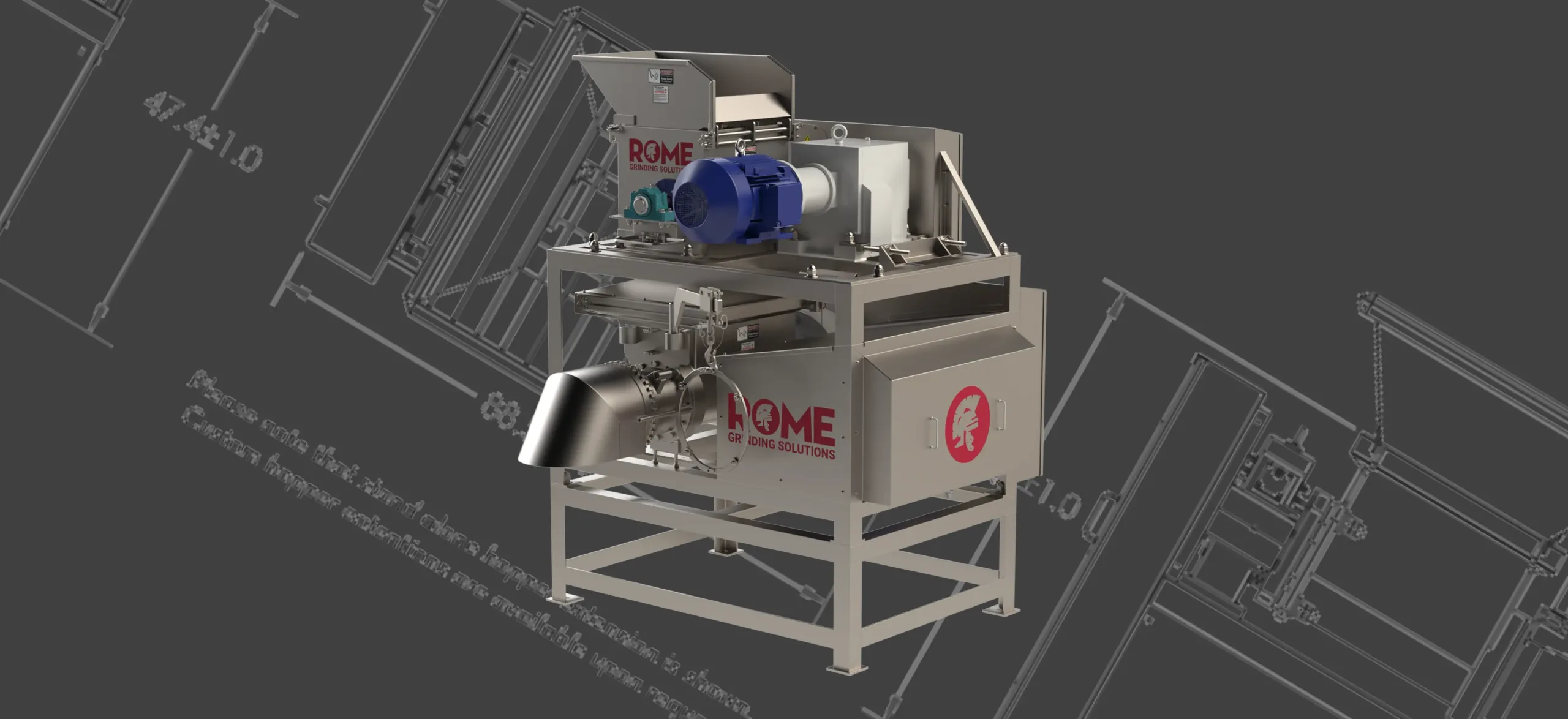

Industrial food production just got a lot more powerful. Rome Grinding Solutions is proud to unveil The Colossus Series—our most advanced, efficient, and ambitious grinder.

As the food production landscape evolves, so does the demand for more intelligent systems that maximize throughput, optimize labor usage, and ensure food safety. The Colossus Series does all this and more, ushering in a new era of dual-stage grinding.

What Is the Colossus?

The Colossus is a two-stage grinding solution engineered to streamline frozen block processing while boosting productivity. It provides a pre-breaking system, feeding directly from the upper grinder (the Colossus) into a lower-mounted Titan or Maximus.

This revolutionary design eliminates the need for separate feed equipment between stages. The result? Fewer steps, fewer machines, less floor space, less mess, and much more efficiency.

One Unified Frame. One Serious Output.

The Colossus isn’t just another grinder. It’s a complete frozen block grinding system built on a custom-engineered frame that perfectly aligns both grinders. This engineered structure ensures maximum stability, maintenance, and sanitation access.

Rome will offer the Colossus Series mated with grinders in the Titan Series or Maximus Series, which are configured to meet your production needs right out of the gate. However, suppose you already own a Titan or Maximus. In that case, Rome can assess your setup and potentially convert your existing grinder to pair with the Colossus frame, eliminating the need to purchase a brand-new unit.

“Built for heavy-duty, dual-stage grinding, The Colossus breaks down the toughest products while delivering a consistent, high-quality grind with minimal effort, ” said Deven Paulsen, Lead Engineer at Rome.

What Makes the Colossus Different?

- Dual‑Stage System in One Unit: Pre‑break and initial grind are built into one frame, resulting in less handling and faster workflow.

- Custom Frame Design: Engineered frame to align both grinders, ensuring consistency and safety.

- Extreme Cold Handling: Built to grind frozen or tempered frozen product without pre-tempering, protecting equipment further down the line and reducing prep time.

- Space & Cost Efficiency: Rather than two separate machines (plus conveyors/feeders), the Colossus setup saves floor space, energy, and capital investment.

Designed TO BE MAINTAINED for the Demands of Tomorrow

Whether you’re producing ground beef, poultry, pet food, or alternative proteins, The Colossus Series gives your operation the power and precision to scale confidently. It’s the ideal solution for:

- Large-scale processors looking to consolidate floor space

- Facilities with labor shortages requiring greater automation

- Operations with demanding sanitation and food safety standards

- Teams aiming to reduce maintenance and material handling

- Operations grinding untempered frozen block that traditional frozen block grinders have difficulty with

Ready to Power Up?

The Colossus Series is built for the food producers who push boundaries and demand better. It’s the biggest thing we’ve ever built and the most efficient way to grind.

Stay tuned for more details, specs, and videos as we prepare for the Colossus Series launch at IPPE.

1427 Western Avenue

Sheldon, IA 51201

PO Box 186

800-443-0557