MEET THE COLOSSUS

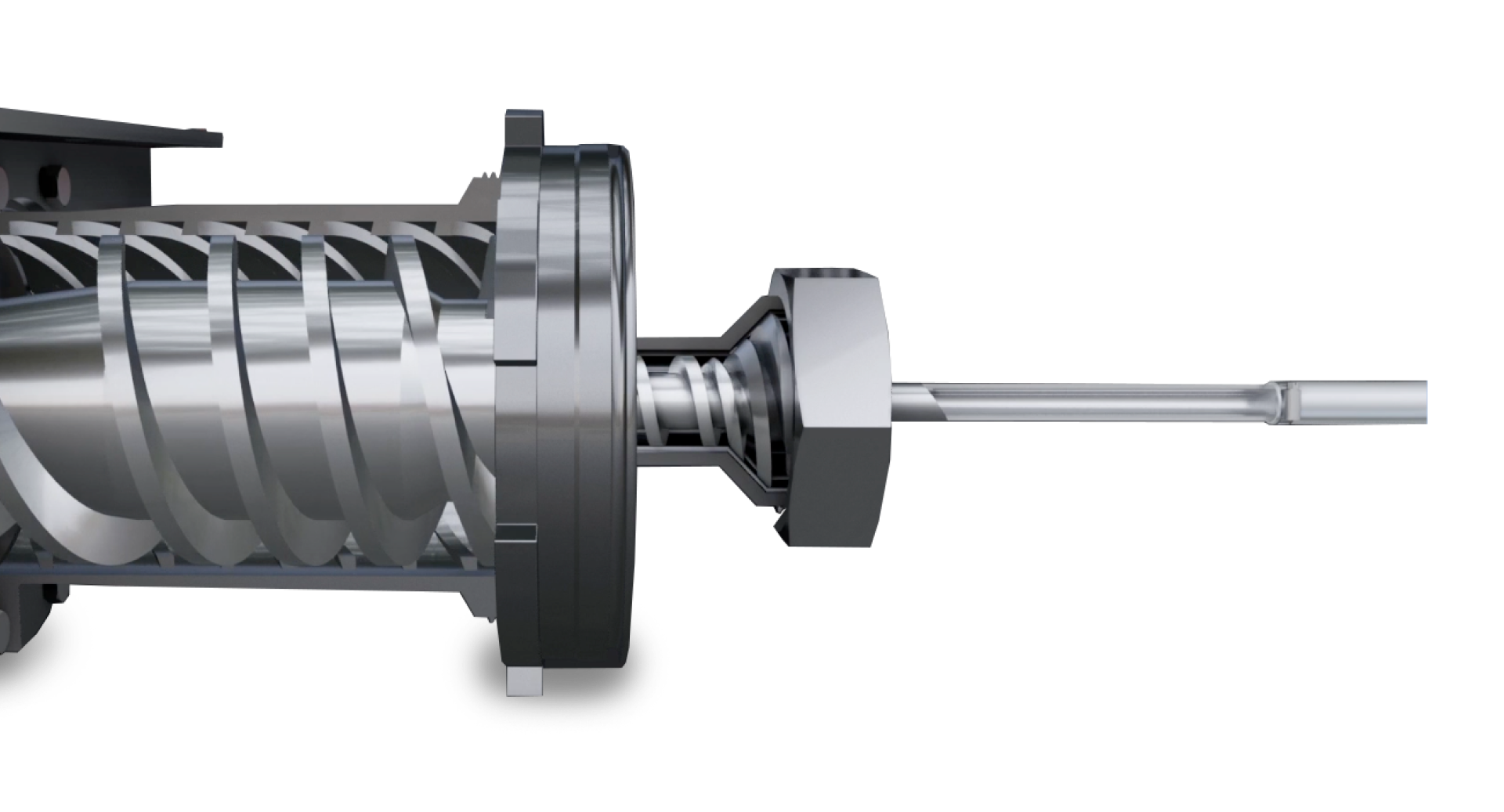

Introducing the Colossus Series, Rome’s dual-stage grinding system designed to set a new standard in food production. Combining a pre‑breaker stage with a Titan or Maximus grinder under one unified frame, the Colossus delivers massive throughput for frozen and tempered products in one streamlined machine.

Available in two heavy-duty models, the Colossus 1109 features an 11-inch grinder plate and a 100–125 horsepower setup ideal for facilities grinding tempered or frozen products that require a high yield. The Colossus 1612 has a 16-inch plate and a 125–150 horsepower configuration for even greater throughput, making it the go-to solution for high-capacity operations working with frozen blocks, dense inputs, or byproducts. Both models are designed as dual-stage systems, pairing a powerful pre-breaker with either a Titan or Maximus grinder, to maximize performance across demanding applications.

COLOSSUS 1109 PARTS & ACCESSORIES

Inserts • Orifice Plates • Knife Holders • Tension Springs • Centering Pins • Bushings • Pulleys •Belts • Motors • VFD/Soft-Starts • Adaptor Plates • Bearings & Seals • Barrels • Motors • Impellers • Chamber Rings • Gearboxes • Augers/Feedscrews • Hoppers • Retaining Rings • Bone Collection System

COLOSSUS 1612 PARTS & ACCESSORIES

Inserts • Orifice Plates • Knife Holders • Tension Springs • Centering Pins • Bushings • Pulleys •Belts • Motors • VFD/Soft-Starts • Adaptor Plates • Bearings & Seals • Barrels • Motors • Impellers • Chamber Rings • Gearboxes • Augers/Feedscrews • Hoppers • Retaining Rings • Bone Collection System

THE BEST GRINDER FOR YOU STARTS WITH YOUR NEEDS

COLOSSUS 1109

Grinder Type

Pre Breaker and

Grinder/Maximus Series

Plate Diameter

11″

Initial Grind

250-400 lbs/min

Final Grind

NA

Voltage

208/240 480V 3 PH

Horsepower

Up to 100-125hp

DPA

Y

TPA

Y

COLOSSUS 1612

Grinder Type

Pre Breaker and

Grinder/Maximus Series

Plate Diameter

16″

Initial Grind

250-400 lbs/min

Final Grind

NA

Voltage

208/240 480V 3 PH

Horsepower

Up to 125-150hp

DPA

N

TPA

N

Initial grind rates are figured using 3/4″ hole plates or larger

Final grind rates are figured using 1/8″ hole or larger

Frozen Block rates are figured using a 1″ hole plate or larger

Bone Grinder rates are figured using 5/8″ hole plate or larger

| Grinder | Grinder Type |

Plate Diameter |

Initial Grind |

Final Grind |

Voltage | Horsepower | DPA | TPA |

|---|---|---|---|---|---|---|---|---|

| COLOSSUS 1109 |

Pre Breaker and Grinder/Maximus Series |

11″ | 250-400 lbs/min | N/A | 208/240 480V 3 PH |

Up to 100-125hp |

Y | Y |

| COLOSSUS 1612 |

Pre Breaker and Grinder/Maximus Series |

16” | 250-400 lbs/min | N/A | 208/240 480V 3 PH |

Up to 125-150hp |

N | N |

Initial grind rates are figured using 3/4″ hole plates or larger

Final grind rates are figured using 1/8″ hole or larger

Frozen Block rates are figured using a 1″ hole plate or larger

Bone Grinder rates are figured using 5/8″ hole plate or larger

Optimize the COLOSSUS With Our

ROME RECLAIM SYSTEM (RRS)

Add the industry’s most cost-effective bone collection and reclaim solution to the Colossus in just ten minutes. Its intuitive setup ensures quick sanitation and no extra power sources, helping you manage waste and boost your bottom line confidently.

THE ROME FAMILY OF INDUSTRIAL GRINDERS

Explore our range of custom-built grinders for food production, designed to handle 6,000 to 150,000 pounds per hour in various industries. Our in-house engineering, advanced CNC machining, and dependable customer service are here to provide the ideal equipment for your operation.

1427 Western Avenue

Sheldon, IA 51201

PO Box 186

800-443-0557