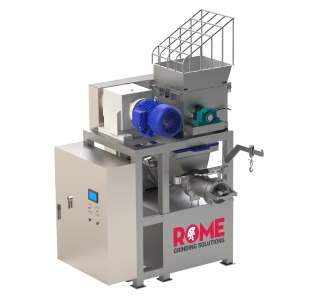

YES, WE GRIND THAT.

At Rome Grinding Solutions, we are dedicated to supplying high quality equipment tailored to the evolving needs of the food production industry. For decades, Rome customers have relied on us to help them produce beef, pork, poultry, dairy products, seafood, fruit, vegetables, flavoring ingredients, and pet food, as well as to render fat and bone safely and efficiently.

FIND YOUR INDUSTRIAL GRINDING SOLUTIONS AT ROME.

Beef GRINDERS

Find the right high quality equipment for your beef production needs, from high volume facilities handling frozen blocks to smaller facilities and fresh materials.

PORK GRINDERS

Customize your Rome grinder with agitating hoppers in order to keep sticky pork products from bridging or becoming overworked due to higher fat content.

POULTRY GRINDERS

Get the exact ground chicken and ground turkey texture and consistency you need in a single pass with Rome Dual Plate Assembly (DPA) or Triple Plate Assembly (TPA).

DAIRY GRINDERS

Reduce dairy product waste and increase production yield through reliably consistent reduction and sanitary design for different kinds of cheeses with varying moisture levels.

SEAFOOD GRINDERS

Grind different sizes and species of fish, crab, and oysters efficiently and effectively to the precise texture and consistency you want, while reducing unwanted parts with Rome Dual Plate Assembly (DPA) or Triple Plate Assembly (TPA).

RENDERING GRINDERS

Confidently render bone or inedible fat-based products with the full line of durable equipment and components manufactured by Rome since 1977.

PET FOOD GRINDERS

Safely integrate a variety of frozen ingredients into your pet food product mix and handle a wide range of wet and dry pet food ingredients while preventing cross-contamination and maintaining product integrity.

Fruit, Vegetable & Ingredients GRINDERS

Use Rome Grinding Solutions to get more of your produce, fruits and vegetables, including root vegetables and leafy greens for sauces, juices, baby food, fillings, purees, or powders to the desired texture and consistency.

EXPLORE OUR INNOVATIVE GRINDING EQUIPMENT

1427 Western Avenue

Sheldon, IA 51201

PO Box 186

800-443-0557